Compared to traditional garages, shipping containers provide a lower cost and more cost-effective solution for affordable storage. However, the foundation is where most DIY projects run into trouble.

Here’s what often happens: your container is delivered, and you’re excited to start creating your garage. You might think placing it on some concrete blocks is enough since it’s a heavy steel box weighing over 8,000 pounds empty. But delivery methods and site-specific requirements can affect the overall cost and success of your build.

Then the inspector arrives, or winter causes one corner to lift, jamming your doors, or a storm moves your “temporary” garage made of multiple containers. Container buildings are versatile and used for garages, houses, and construction sites, but building codes don’t just consider weight. They require proper anchoring, the ability to withstand local harsh weather, and structural integrity like any permanent building.

If your foundation isn’t done correctly, you risk costly repairs, failed inspections, and safety hazards that make your garage less secure. This guide will walk you through the right foundation choices for your storage area, what can cause problems, and what inspectors expect. Plus, using shipping containers is an eco-friendly solution for those wanting a greener option.

Introduction to Shipping Containers

Shipping containers have rapidly become a go-to solution for anyone looking to build a garage, carport, or extra storage space. Their appeal lies in their unmatched durability and versatility—these containers are constructed from industrial-grade corten steel, making them incredibly resistant to harsh weather, fire, and pests. Whether you’re planning to build a single container garage or a larger structure with multiple containers, shipping containers offer a cost effective and eco friendly alternative to traditional construction materials.

One of the biggest advantages of using shipping containers for your garage is the quick setup. Unlike traditional garages that require extensive framing and long build times, a container garage can be delivered and assembled in a fraction of the time, saving you both labor and material costs. Their modular design means you can easily expand your storage needs by adding more containers as your requirements grow. Plus, the industrial look of shipping containers is an attractive option for those seeking a modern, unique structure that stands out on any property.

Shipping containers are also a sustainable choice. Repurposing used containers reduces waste and makes use of existing materials, aligning with eco friendly building practices. Whether you need a secure place to store vehicles, equipment, or simply want more space, shipping containers provide a durable, cost effective, and flexible solution for any garage or storage project.

Design Concepts for Container Garages

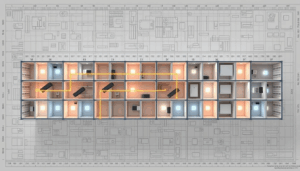

When designing a container garage, the possibilities are nearly endless thanks to the flexibility of shipping containers. One popular approach is to use two shipping containers placed parallel to each other, then add a roof structure across the top to create a spacious, covered area. This setup not only maximizes storage space but also allows you to store multiple vehicles, equipment, or even create a workshop area between the containers.

If your storage needs are more modest, just one shipping container can be transformed into a secure and functional garage or storage unit. Single container garages are ideal for storing a car, motorcycle, or tools, and can be customized with personnel doors, windows, and insulation to improve comfort and usability. For those needing even more space, multiple containers can be combined in creative layouts—side by side, end to end, or even stacked—to create a truly custom container garage.

Adding features like garage doors, personnel doors, and insulation can further enhance your container garage, making it suitable for year-round use and protecting your vehicles and belongings from the elements. Whether you’re looking to create a simple storage area or a fully equipped workshop, shipping containers offer the flexibility to design a garage that fits your specific needs and available space.

Cars Fit and Container Size

A key consideration when planning your container garage is making sure your vehicles and equipment will fit comfortably inside. Most cars can easily fit into a standard shipping container, which typically measures 8 feet wide, 8.5 feet high, and comes in lengths of either 20 or 40 feet. This makes a single container garage a practical solution for storing a car, motorcycle, or even small equipment, while still leaving room for extra storage space.

If you need to store larger vehicles, multiple cars, or bulky equipment, you might opt for a container garage built from two shipping containers or more. This approach provides more space and flexibility, allowing you to create a structure that meets your exact storage needs. It’s important to match the size of your container to the vehicles or items you plan to store—measuring both the available space inside the container and the dimensions of your car or equipment ensures a proper fit and easy access.

Whether you’re using a single container or building a larger structure, shipping containers offer a versatile and secure way to store vehicles, tools, and other valuables. Their modular design means you can start small and expand as your needs grow, making them a smart, cost effective choice for any garage project.

Common Foundations for Shipping Container Garages

Every region has preferred foundation types to meet storage needs like a standard garage, but these six options cover 95% of what DIY builders choose. Each has specific use cases where it shines—and situations where it’s wrong for the job. A strong frame, often made from galvanized steel, is essential for supporting the weight and structure of a shipping container garage, ensuring durability and stability for various applications.

Concrete Pier Footings

What it is: Individual concrete pillars placed under the container’s corners and sometimes mid-span points. Think deck footings sized for the container’s weight.

Pros: Cost effective solution for smaller garages, uses less concrete than a slab, quick to install, allows good drainage under the container. Ideal for stable soil and moderate climates.

Cons: Can fail in frost zones if not deep enough. Requires precise layout; misaligned piers are hard to fix.

Best for: 20-foot containers in mild climates, budget builds without a finished floor.

Cost range: $50-75 per pier (DIY materials).

Slab-on-Grade Foundation

What it is: A continuous concrete slab supporting two shipping containers and serving as a finished garage floor.

Pros: Provides bulletproof support, keeps pests out, distributes weight evenly. Inspectors favor slabs for structural integrity.

Cons: Expensive—3-5x the cost of piers. Requires excavation and concrete work. Mistakes require starting over.

Best for: Large garages, soft soils, permanent installations needing a finished floor.

Cost range: $4-25 per square foot depending on thickness and location.

Grade Beam (Strip Footing)

What it is: Continuous concrete strip poured around the container’s perimeter or load-bearing lines, offering perimeter support without a full slab.

Pros: Better than piers for weak soils, uses less concrete than slab, blocks critters, provides strong anchor points.

Cons: Requires significant concrete work, no finished floor like a slab.

Best for: Medium-sized garages, questionable soil bearing capacity.

Cost range: 70-80% of slab cost.

Frost-Protected Shallow Foundation (FPSF)

What it is: Shallow slab or footing using rigid foam insulation to prevent frost heave by trapping ground heat.

Pros: Allows shallow excavation in frost zones, effective when done right.

Cons: Technical to execute, requires following specific guidelines.

Best for: Cold climates with unheated garages.

Cost range: Moderate, similar to shallow footings plus insulation.

Helical Piles (Screw Piers)

What it is: Steel screw-in anchors drilled into the ground, providing support and uplift resistance.

Pros: Minimal excavation, excellent uplift resistance for high-wind zones, immediate load capacity.

Cons: Usually professional installation needed, higher upfront cost, requires machinery access.

Best for: High-wind areas, difficult sites, flood-prone locations.

Cost range: $300-600 per pile installed.

Gravel Pad

What it is: Compacted crushed stone bed contained by lumber, a simple level, well-draining surface.

Pros: Cheap, excellent drainage, keeps container off wet ground.

Cons: No anchoring, minimal resistance to shifting, usually not accepted for permanent garages without tie-downs.

Best for: Temporary installations, mild climates.

Cost range: Low (gravel plus lumber costs).

What Inspectors Want to See for Your Container Garage Foundation

Building codes treat shipping container garages like any other building. The 2021 International Building Code requires:

Code-Compliant Foundations

Your container must rest on foundations meeting standard building design criteria. “Just set it on blocks” won’t pass. Footings must extend to proper depth, have adequate size, and use durable construction materials like concrete or engineered steel.

Proper Anchoring

Weight alone won’t keep your container in place. Codes require anchoring to provide a continuous load path for all loads:

- Hurricane straps or anchor bolts at corner castings (minimum)

- Steel plates embedded in concrete with welded connections

- Engineered twist-lock connectors bolted through foundation

Inspectors reject any container that moves on its foundation.

Frost Depth Compliance

In cold climates, footings must extend below frost line or use approved FPSF. Small detached garages under 600 sq ft may have exceptions, but larger container garages do not.

Drainage and Ventilation

If on piers, the space underneath is treated like a crawlspace, requiring ventilation and access. Marine-grade plywood floors need protection, usually by elevating on piers or slabs.

Foundations That Fail Inspections (And Why)

No Anchoring (“Just Set On Blocks”)

Assuming container weight holds it in place fails modern codes. Storms can move even loaded containers. Lack of anchoring causes failed inspections and safety risks, especially if using a used container .

Shallow Piers in Frost Zones

Short piers not reaching frost depth can heave, causing doors to jam and structural damage.

Gravel Pads Without Tie-Downs

Gravel supports weight but provides no anchoring, risking shifting and rejection by inspectors.

Inadequate Tie-Downs

Using insufficient anchor methods or unengineered plans fails especially in high-wind zones.

Floating Slabs Over Size Limits

Simple shallow slabs in frost zones without proper depth violate codes and require costly fixes.

Lack of Permits or Rejected Foundations

Wood beam or railroad tie foundations are often rejected for permanent garages. Permits and approved foundation types are essential.

Regional Foundation Considerations

Cold Climates

Footings must extend below frost line or use FPSF insulation to prevent frost heave.

Hot & Dry Climates

Continuous footings or slabs spread loads better than piers; soil watering may prevent excessive shrinkage.

High-Wind and Hurricane Zones

Strong anchoring with engineered tie-downs is critical; professional design may be required.

Seismic Zones

Anchor bolts, shear keys, and reinforced footings handle lateral loads and ensure structural integrity.

Flood Zones

Elevated foundations with deep footings and drainage measures protect against water forces.

Soil Bearing Capacity

Soft soils require larger footings or slabs to prevent settling.

Cost & Complexity Overview

Foundation Type | Cost Range | Complexity | Inspection Risk | Best Use |

|---|---|---|---|---|

Gravel Pad | Low ($200-500) | Easy (DIY weekend) | High without anchors | Temporary, mild climates |

Timber Beam/Railroad | Low ($100-300) | Easy (basic leveling) | High for permanent | Temporary or agricultural use |

Concrete Pier Footings | Moderate ($50-75/pier) | Medium (layout, pour) | Low if anchored | Small to medium garages |

Helical Piles | High ($300-600/pile) | Low (pro install) | Very low | Difficult sites, high winds |

Grade Beam | Moderate-High | High (trenching) | Low | Medium garages, weak soils |

Slab-on-Grade | High ($4-25/sq ft) | High (excavation) | Very low | Large, permanent garages |

Best Practices for DIY Container Garage Foundations

- Consult Local Regulations Early: Talk to your building department about permits, foundation codes, and tie-down requirements.

- Choose Foundation by Site Conditions: Consider climate, soil, and garage size; consult a structural engineer for advice.

- Support at Corner Castings: Align footings under container corners; add mid-span support for 40-foot containers.

- Anchor Properly: Use welded plates, twist-lock anchors, or side mounts with proper concrete anchors.

- Ensure Drainage: Grade soil away from foundation; use gravel pads for moisture control.

- Document Inspections: Get pre-pour inspections, take photos of footings and rebar.

- Plan Utilities: Include conduit or plumbing pathways before pouring concrete.

- Hire Professionals for Critical Steps: Use concrete contractors, welders, and engineers as needed.

Additional Considerations for Your Shipping Container Garage Foundation

When planning your shipping container garage, consider insulation, ventilation, and lighting to ensure a comfortable and functional space. Usability and design are key—think about how garage doors can be installed for easy access, and how modifying a wall or the back wall can create extra storage or workspace.

Adding a canopy or container roof can provide additional shelter and protection for vehicles and storage areas. Options like metal canopies, fabric canopies, or custom-built container roofs help shield your garage from weather elements and expand usable space.

Interior walls can be removed or reconfigured to create open, accessible spaces, and custom features can be created to fit your specific needs. Attaching a container against the back wall can enhance storage and improve the overall layout.

Shipping containers are versatile—they can be used not only for garages, but also for houses and other types of container buildings.

Concrete Foundation Types and Their Impact

Choosing the right concrete foundation affects not only structural integrity but also the usability of your container garage, allowing for extra space . For example, a slab-on-grade foundation provides a smooth, finished floor ideal for workshops or vehicle maintenance, while pier footings leave space underneath for ventilation but may limit floor finishing options. Additionally, grade beams offer a middle ground by providing continuous perimeter support without the full coverage of a slab, which can be beneficial in areas with moderate soil conditions. Frost-protected shallow foundations (FPSF) are another option especially suited for cold climates, using insulation to prevent frost heave and maintain foundation stability.

Importance of Soil Testing

Before deciding on a foundation type, soil testing is highly recommended. Soil bearing capacity, moisture content, and composition directly influence foundation stability. Testing helps avoid future settling issues that can compromise the container garage structure. For instance, clay-heavy soils may expand and contract significantly with moisture changes, requiring deeper or more reinforced foundations. Sandy soils, on the other hand, may require compaction or additional stabilization to prevent shifting.

Insulation and Moisture Barriers

In addition to foundation type, consider adding a moisture barrier beneath concrete slabs to prevent dampness and mold. For garages used as workshops or storage for sensitive equipment, proper insulation combined with a solid foundation enhances comfort and protects your belongings. Vapor barriers, damp-proof membranes, and insulation boards can all be integrated into the foundation system to improve energy efficiency and indoor air quality. Proper drainage around the foundation also plays a critical role in preventing water intrusion.

Foundation and Local Regulations

Legal requirements vary widely by location. Some jurisdictions may require engineered foundation plans or specific anchoring methods, especially in hurricane or seismic zones. Engaging with local building officials early in the planning process can save time and ensure compliance. Understanding zoning laws, setback requirements, and environmental regulations is also important to avoid costly delays or modifications. Some areas may have restrictions on foundation types or require permits for excavation and construction.

Eco Friendly Solutions

If sustainability is a priority, look into eco friendly foundation options for your shipping container carport like recycled concrete aggregate or insulated concrete forms. These can reduce environmental impact while providing durable support for your container garage. Additionally, using locally sourced materials, minimizing waste during construction, and designing foundations that reduce material usage contribute to a greener build. Some modern foundation techniques also incorporate permeable surfaces to allow natural water absorption and reduce runoff.

Conclusion

Your shipping container garage is more than a box—it’s a permanent structure requiring a code-compliant foundation. The foundation ensures structural integrity, legal compliance, and long-term durability against harsh weather and soil conditions.

Getting the foundation right saves money, time, and headaches. It guarantees your garage passes inspections, remains level, and protects your vehicles and equipment.

Ready to build? Choose the right foundation for your site, follow local regulations, anchor properly, and don’t cut corners. Your future self—and your bank account—will thank you.

Download our free container garage floor plans with foundation specs and permitting guidance to get started today.