Shipping Container Garage Renovation Cost: DIY Conversion Guide — Why Your Project Could Cost $6K or $26K and How to Plan Smarter

You can buy the same size shipping container as your neighbor and still end up spending 4x more on your garage conversion. Why? Because the real cost isn’t in the container — it’s in what comes next. From container grade and structural cuts to site prep surprises and permit fees, the budget-shifting variables stack fast. If you’ve read “you can build a garage for under $5,000,” you’re missing the full picture. Even basic modifications like adding doors, windows, and insulation typically cost a few hundred to a few thousand dollars, and total renovation costs can easily reach several thousand dollars depending on the scope.

Welcome to the only DIY container conversion guide grounded in real project data, inspector insight, and regional cost modeling.

Introduction to Container Conversion

Shipping container garages are quickly becoming a go-to solution for homeowners and DIY enthusiasts looking for a durable, cost-effective, and flexible alternative to traditional garages. Converting a shipping container into a functional garage starts with careful planning—choosing the right container, understanding your storage and vehicle needs, and ensuring compliance with local building codes. With the right approach, a shipping container garage can offer secure, weather-resistant storage for vehicles, tools, and equipment. By weighing the benefits and key considerations of container conversion, you can make informed decisions that keep your project on track, on budget, and fully compliant with local regulations.

The Hidden Variable Problem: Why DIY Container Conversions Confuse Even Smart Builders

You might start with a clean metal box and a clear vision — but sticker shock tends to hit halfway through. Why? Because most DIYers focus on container cost and overlook the five cascading cost drivers:

-

Container Grade

-

Upgrade Requirements

-

Site Preparation

-

Permitting

-

Long-Term Use Case

The trap isn’t in ambition — it’s in underestimating how these variables multiply each other. Builders routinely under-budget by 50–80%. Not because they’re naive, but because the online planning tools are too shallow. If you’re standing on your lot thinking, “Can I really convert this container into a garage without burning cash on mistakes?” — this article is for you.

We’re breaking down how two identical-looking projects can land at $4,500 and $28,000 — and how to map where your build will fall.

Container Garage Benefits

One of the standout benefits of shipping container garages is their impressive cost effectiveness. Compared to traditional construction methods, using a shipping container can save you thousands of dollars in both construction materials and labor. Shipping containers are engineered to withstand extreme weather conditions, making them a reliable choice for secure storage of vehicles and valuable equipment. Their robust steel construction means they’re built to last, and with a range of customization options, container garages can be tailored to meet your specific storage needs. Whether you need a simple space to store items or a fully outfitted workshop, container garages offer a practical, versatile, and secure solution that’s hard to beat for value and durability.

The Five Interconnected Cost Drivers — and How They Multiply Each Other

Container renovation costs don’t add up — they stack. That means one weak decision (like going cheap on the container) can trigger expensive fixes down the line. Let’s unpack the five factors that drive these swings, including site prep surprises—where site conditions such as soil type, slope, and drainage can significantly impact overall renovation costs.

1. Container Grade

A lower-grade container may look like a win at $1,500 — until it needs $5,000 worth of remediation. A used container may be more affordable, but it often requires more repairs, while a one trip container (a cargo container that has only made one cargo trip) is nearly new and may offer better value for certain projects. Case in point:

-

A Grade B unit purchased for $684 in New Zealand required $6,840 in roof and base frame repairs before it could even be sealed.

The grade you choose dictates rust risk, modification difficulty, and insulation compatibility from the start.

2. Structural Modifications

Every cut weakens the container’s structural logic — especially large cuts for garage doors. Maintaining structural integrity is crucial when making these modifications, and reinforcement is often necessary to ensure the container remains safe and functional. Without reinforcement, your container loses its load-bearing properties.

-

Basic cuts cost $500–$800 per opening

-

Large garage door cutouts = $1,000–$3,000 in framing and welding

-

Older containers often require extra steel bracing due to rust stress fractures

3. Interior Finish Levels

Interior choices swing your budget by thousands:

-

$1.2K: Plywood floor, vinyl sheet, exposed studs

-

$10K+: Epoxy floor, MR drywall or metal panels, shop-ready lighting, and integrated odor control. Proper electrical wiring should be installed by a professional to ensure safety and compliance with building codes.

Investing here pays off — but only when it aligns with actual use.

4. Intended Use

Storage garage? Or mini mechanical workshop? Costs shift radically:

-

Passive storage: Minimal insulation + lighting = $2K–$4K total

-

Workshop:

-

HVAC: $2.5K–$5K

-

220V Electrical: $3.8K

-

Spray Foam Insulation: $3.6K

-

Custom Storage Systems: $2K+

If you plan to store a car or multiple cars, pay special attention to container size, access for vehicles, and proper ventilation to ensure the space is suitable for cars.

Define use early — or risk designing for a garage you’ll never use.

5. Site Access + Region

Your geography is a multiplier:

-

Container delivery short distance: $300; off-grid mountain parcel? $1.5K+

-

Foundation costs:

-

Easy pad or piers on flat land: $3.6K–$5.1K

-

Slab on sloped property with drainage: $12K–$15K+

Your specific location will affect delivery logistics, foundation requirements, and compliance with local building codes.

☝️ ModBetter Insight: High-spec upgrades amplify low-grade problems. A new HVAC system won’t fix rust holes in the container roof. Think strategically: costs don’t add — they cascade.

Why Permits, Site Prep, and Your ZIP Code Can Blow Up Your Budget

Even if you ace design and containers, your jurisdiction may still wreck your budget.

Permitting Chaos by Region

-

Rural counties (minimal oversight): $500–$1,200

-

Urban areas with IBC Section 3115 compliance: $3,500–$6,000

-

Added engineering stamp for cuts or roof loads: +$700–$2,300

Tip: Municipal interpretations of IBC 3115 vary wildly. Some allow containers by-right; others require case-by-case structural proofs.

Foundation Rule Complications

Just because others did gravel and blocks doesn’t mean your site can.

-

Frost zone? Vapor barriers and insulation required → slab at $6.4K+. A concrete slab foundation is often the optimal choice for stability and durability, but some projects may use alternative foundation methods to minimize concrete use and save costs.

-

High water table? Raised pier system or grid footing: $5,100+

Don’t guesstimate — get a soil/geotech report early.

Electrical Hookups

Trenching impact is massive:

-

Distance < 20 ft: $1.2K

-

500 ft rural run + transformer? $12.2K+

Verify your panel load and distance before drawing outlet locations in SketchUp. All electrical wiring and systems should be properly installed by licensed professionals to ensure safety and code compliance.

Site Prep Surprises

-

Flat lots: Driveway + delivery = $2K

-

Sloped terrain? Retaining walls + drainage = $10K+

Forget “free” land — bad access eats budgets faster than any door upgrade.

Climate Zone Costs

|

Region |

Required Upgrades |

Added Cost Estimate |

|---|---|---|

|

Northern |

R-30/R-19 insulation + vapor wraps |

$3.6K–$5.2K |

|

Coastal |

Rust conversion + prep primer coating |

$1K–$1.5K |

|

Wind Zone (III) |

Anchors + uplift resistance upgrades |

$1.8K–$3.2K |

⚠️ Pattern Alert: Your region can double your budget before breaking ground. Don’t trust national averages — model your ZIP with regional overlays.

Eco Friendly Container Conversion

Opting for a shipping container conversion is not just a smart financial move—it’s also an eco friendly choice. By repurposing used shipping containers, you’re giving new life to materials that might otherwise go to waste, reducing the demand for new construction materials and minimizing your project’s environmental impact. Shipping containers can be insulated and upgraded for energy efficiency, further lowering your garage’s carbon footprint. As sustainability becomes a bigger priority for homeowners, eco friendly container conversions stand out as a responsible way to build a garage that’s both functional and kind to the planet.

Should You Ever Go Cheap? Understanding Container Grades and False Economies

You can’t talk price without talking condition. Here’s how container grades compare:

|

Grade |

Cost |

Condition |

Long-Term Risk |

|---|---|---|---|

|

New/1T |

$5K–$7K |

Like-new, minimal rust, standard size |

Low (< $500/10 yrs) |

|

Premium |

$3K–$5K |

< 8 yrs old, cosmetic wear acceptable |

Medium (< $1.5K/10 yrs) |

|

Grade A |

$1.9K–$2.5K |

8+ yrs old, minor rust or damage |

Medium–High |

|

Grade B/C |

< $1.5K |

Known problems (roof, rust, floor, doors) |

High ($2K–$6K fixes) |

Real-World Case: A ModBetter builder in New Mexico chose a $2K Grade A unit — but had to replace the floor ($1.1K) and weld over roof leaks ($800). The $3.9K premium unit next door? Zero issues.

Container condition affects:

-

Cut modification success (older steel warps under heat)

-

Insulation adhesion viability (rust = spray foam failure)

-

Flooring hygiene and strength (rotted plywood = complete tear-out)

💡 Strategic Rule: If lifespan matters and you’re not a welder — buy better once. Upfront extra = long-term savings. When purchasing a high-quality container, even if the initial cost is higher, you can save money on repairs and ensure better long-term performance.

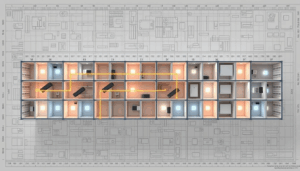

Storage Solutions for Container Garages

Maximizing storage is key to getting the most out of your container garage. With smart planning, you can transform a simple container into an organized, clutter-free space. Installing shelving, racks, and cabinets allows you to store tools, equipment, and seasonal items efficiently. Overhead storage solutions—like ceiling-mounted racks or hoists—make use of vertical space, keeping the floor clear for vehicles or larger equipment. By incorporating these storage solutions, container garages become highly adaptable, making them ideal for anyone needing to store multiple vehicles or a wide range of gear.

Maximizing Space with Container Garages

To truly maximize the space in your container garage, thoughtful planning and design are essential. Using multiple containers or placing two shipping containers side by side can create a larger, more versatile garage that rivals a standard garage in size and functionality. Adding roll up doors, windows, and proper insulation not only improves access and comfort but also enhances the usability of the space year-round. By tailoring the layout and features to your specific needs—whether that’s extra room for a workshop, more storage, or better climate control—you can create a container garage that’s both efficient and cost effective. The flexibility of shipping container garages means you can design a storage solution that fits your property, your budget, and your lifestyle.

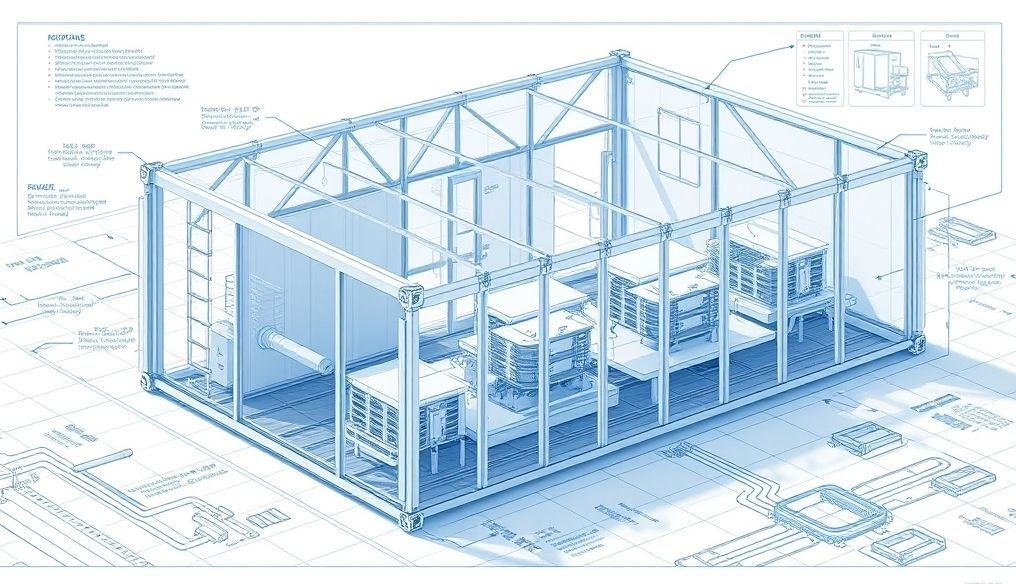

How to Actually Budget a DIY Container Garage: ModBetter’s Phased Framework

The smartest builds don’t budget by line item — they budget by phase. Significant cost savings can be achieved by carefully planning each phase and considering options like using two containers instead of traditional construction. Use this 5-step workflow to define, scope, and sequence your container garage without flying blind.

Phase 1: Container Acquisition

-

Choose grade based on how long you expect it to last — and your repair skills

-

Budget +10–15% for undiscovered remediation (e.g. rust sealing, floor cuts)

Phase 2: Site & Permitting Planning

☑️ Lookup IBC 3115 adoption locally

☑️ Talk to permitting office about anchoring/foundation criteria

☑️ Order soil + drainage study before any slab decisions

Phase 3: Use Case + Systems Layer

-

Define your Garage Class (see below). Creating a custom layout and systems plan tailored to your needs will help ensure the finished garage is both functional and cost effective.

-

Budget accordingly:

-

HVAC needs = $3K–$5K

-

Electrical 220V = $3.8K

-

Ventilation vs. true climate control? Big delta in install + utility cost

Phase 4: Envelope Design

-

Minimize large wall removals → every cut = $

-

Use container roll-up doors that avoid full header cuts

-

Reinforcement = $1K–$3K depending on opening size

Phase 5: Insulation & Finish Planning

-

Climate matters:

-

R-13 fiberglass kit? OK for storage in Arizona

-

R-30 foam? Non-negotiable in Michigan

-

-

Prefinish walls in a way that allows future upgrades without demo

🔒 Budget Buffer Rule: Unless your site is fully mapped with permits in-hand, pad your total budget by 20–30%.

What to Do Next: Tools, Kits, and Prep Steps to Launch With Confidence

Before cutting or customizing, nail these early steps: Coordinate with your supplier to deliver the container to your site at the right time, ensuring access and site readiness.

Run Container Quality Checks

→ Use ModBetter’s Container Grade Evaluation Checklist to audit floor condition, roof dips, rust signs, and mod fit, while also considering the durability shipping containers offer thanks to their corrosion-resistant materials and robust construction.

Begin Site Prep Pricing

Get quotes for:

-

Foundations (piers vs. slab)

-

Delivery and driveway (note: the container garage can often be delivered preassembled or ready-to-use, which can speed up installation and reduce on-site labor)

-

Utility trenching

-

Soil compaction and drainage work

Define Your “Garage Class”

Know your use case term sheet:

-

Tier 1: Passive Storage

-

Basic 15-amp lighting (a storage container can be an ideal solution for basic storage needs, offering security and durability)

-

Minimal insulation

-

Gravel pad or piers → ~$6K–$9K

-

Tier 2: Daily Workshop

-

Spray foam + vapor control

-

HVAC + full electrical

-

Anchored foundation → ~$15K–$22K

-

Tier 3: High-Spec Unit

-

Climate control + sealed floor

-

Security + smart garage

-

Premium wall/ceiling finish → ~$22K–$30K+

Tool + Product Shortlist

-

Roll-up Garage Doors (low-structural-impact, container-ready)

-

Spray Foam Kits (ModBetter-vetted, DIY-safe)

-

Rust Converter Kits (for mid-grade refurb)

-

Delivery and driveway (plan for transport logistics, including the need for appropriate equipment and access to move the container to its final location)

FAQs

Q1: Can I convert a container garage without permits?A: Rare. Even unconditioned storage garages often require permits due to anchoring, electrical, and setback requirements. Check local interpretation of IBC 3115.

Q2: Can I skip a foundation and just use piers or blocks?A: In rare, stable rural soils — yes. But frost zones or drainage issues push inspectors toward slab or engineered piers. Confirm with soil tests first.

Q3: Is spray foam worth the cost?A: In most mixed or cold climates — yes. It handles moisture and thermal transfer better than fiberglass. For hot/dry climates and unconditioned garages, cheaper options may be sufficient.

Q4: Do wind zones really affect my build?A: Absolutely. Containers are heavy but not invincible — wind uplift in coastal zones requires $1K–$3K in anchoring and bracing per code.

Q5: What’s the most common rookie mistake?A: Going for a Grade B container to “save money,” then spending more fixing rust, floors, or warps than you would’ve spent on a better unit upfront.

Q6: Can I use a shipping container garage as the foundation for a small house or container home?A: Yes, shipping containers can be adapted as the foundation or main structure for a small house or container home. However, you’ll need to address insulation, structural modifications, and comply with local building codes to ensure the space is safe and livable.

Final Word: Containers Cost More Than Images Suggest — But Less Than Mistakes Do

Knowing your container garage might cost $4K or $24K isn’t that helpful. Knowing why it costs that is game-changing. You’ve now seen the drivers that shift cost quickly: container grade, structural cuts, climate compatibility, permitting quirks, and design clarity.

Shipping containers offer various configurations, from single-car garages to larger setups using two containers or even 40 ft containers for extra space. They are a cost effective option for a range of projects, including not just garages but also swimming pools and other creative uses.

ModBetter doesn’t sell plans — we decode cost realities. Our job is to help you skip wasted builds, bust false economies, and make your first design the right one.

Start smarter — and build once, not twice.