In two quiet neighborhoods in the Pacific Northwest, two nearly identical backyard garage projects based on shipping container structures set off on seemingly similar paths. One, tucked into Portland’s Madison South community, became a headline-grabbing success story—increasing the home’s value by $80,000 and entering the short-term rental market within six months. The other, started just 20 miles north in Seattle, never crossed the finish line. Midway through construction, it hit a wall of red tape. Despite the same design and intentions, the city issued a stop-work order and eventually deemed the structure unsafe under existing code classifications.

What explains this dramatic divergence? Not engineering. Not design. Not budget. In truth, only one thing changed: the jurisdiction. This is the often invisible, but enormously impactful, architecture of bureaucracy—the codes, policies, and politics that classify, delay, or doom DIY container builds based on how a city defines the word “building.”

In this DIY container conversion guide, we reveal how regulatory factors—not construction missteps—are the real threat and opportunity for container builders. We map how cities like Portland create value from innovation, while others like Seattle erase it mid-weld. Armed with intelligence from two of the nation’s most instructive case studies, here’s how to protect your project’s future before you even buy your first container.

Why So Many Container Projects Fail Before They Begin (And Why It’s Not Your Fault)

If you’re diving into a DIY container conversion expecting your biggest challenges to be welding seams or insulating steel walls, pause right there. For most builders, the real risk lies not in design or craftsmanship, but in code misalignment and bureaucratic blind spots.

Consider this: In the Seattle metro area, container builders face pre-construction permitting and documentation costs that can exceed $40,000—a barrier that disqualifies most projects before a single tool is lifted. Meanwhile, just across the Columbia River in Portland, nearly identical container conversions proceed smoothly with $2,000–$5,000 in permit fees and timelines under 90 days. The location of your project directly impacts cost effectiveness, regulatory requirements, and overall project feasibility, as local codes, delivery logistics, and site setup can vary dramatically.

The critical difference? A single classification word: “building.” While Seattle treats steel containers as foreign artifacts needing commercial-grade scrutiny, Portland recognizes them as residential accessories—compact, sustainable extensions of existing housing. That classification determines everything: fees, timelines, insurance access, loans, and even resale value. The location of your build determines the cost effectiveness of a shipping container garage project, as local regulations and permitting processes can significantly affect your budget and timeline.

Most DIY builders don’t fail because of shoddy work. They’re failed by a system that doesn’t yet know how to interpret what they’re building. And most container tutorials, walkthroughs, or step-by-step guides ignore this completely.

At ModBetter, we analyze more than just a blueprint—we examine what we call the regulatory physics: the unseen forces that determine whether your project creates wealth or sinks your savings. It’s not about building better—it’s about building smarter, by aligning with the invisible rules before metal meets ground.

Understanding Shipping Containers: The Foundation of Every Build

Before you start planning your container garage or carport, it’s crucial to understand the building blocks you’ll be working with. Shipping containers are engineered for strength and durability, making them an attractive option for creating secure, weather-resistant storage space. Most shipping containers are available in standard lengths of 20 or 40 feet, with a width of about 8 feet and heights ranging from 8 to 9.5 feet. This gives you enough space to store most cars, equipment, or even create a functional workshop.

The primary material used in shipping containers is corten steel, renowned for its ability to withstand harsh weather and resist corrosion. This structural integrity is what makes container buildings so popular for garages and carports, especially in areas prone to rain, wind, or snow. When planning your build, consider the specific requirements of your vehicles or equipment—will you need extra height for a truck, or more width for shelving and storage? Also, check your local regulations to ensure your container project meets all legal requirements for container buildings in your area.

By understanding the basics of shipping containers—their sizes, materials, and strengths—you’ll be better equipped to create a durable, functional, and compliant garage or carport that stands the test of time.

The Seattle Model: How Building Code Classifications Kill Container Projects Before They Start

In Seattle, container conversion isn’t just complex—it’s institutionalized as unlikely.

Here’s why: Seattle adheres to a highly customized version of the International Building Code (IBC), layered with local amendments that categorize shipping containers as “nonstandard structures.” That single label pushes them into an entirely different—and costlier—permitting stream.

If you’re in King County intending to build even a modest 320-square-foot container ADU, you’re required to submit a full commercial-level package from the outset. That means:

Engineer-approved structural plans showing reinforcement for wind, snow, and seismic loads, with the choice of construction materials—such as steel containers—directly impacting the permitting process

Holistic site plans stamped by a licensed professional

Energy compliance documentation, including insulation and thermal bridge mitigation

Detailed egress and ventilation solutions beyond what typical ADUs require

While shipping containers are commonly used for temporary storage or shelter at construction sites, using them as permanent garages or living spaces faces much more regulatory scrutiny in Seattle.

Before breaking ground, builders spend $15,000–$40,000 just to pass the regulatory gateway. And even then, city reviewers may impose 120–180 day review periods, especially if the structure lands in a multi-department conflict zone — say, an industrial buffer area with Port of Seattle restrictions. Although container-based builds can offer a significantly lower cost compared to traditional construction, Seattle’s high permitting and engineering fees often erase those savings.

One heavily cited project in Snohomish County racked up nearly $39,669 in pre-construction permit fees, driven by forced commercial valuation models, permit multipliers, and specialized reviews.

City officials route these builds through commercial permitting, despite their residential use, due to their label as “specialized structures.” Unlike a traditional garage, which typically features enclosed ends, a concrete foundation, and a finished interior and is subject to standard residential requirements, container garages are subject to different and often more stringent regulations. And when builders try to shortcut the process via the State’s mobile home classification under the Washington Department of Labor & Industries, they discover the long-term price: limits on where the structure can legally sit, higher property taxes, and insurance headaches that spike premiums or block coverage altogether.

Why the resistance? It’s not just policy—it’s politics. Seattle’s construction community includes strong labor interests wary of prefabrication and container builds that reduce site labor needs. The Port of Seattle actively lobbies against residential encroachment near industrial zones, saying it interferes with freight and maritime infrastructure.

In short, Seattle’s zoning, labor, and industrial stakeholders have aligned, whether intentionally or not, to create a status quo that extinguishes container construction before it breathes.

The Portland Blueprint: How Regulatory Friction Turned Into Value Creation

Meanwhile, just across state lines, Portland has charted a vastly different path—treating container structures not as code anomalies, but as creative housing opportunities.

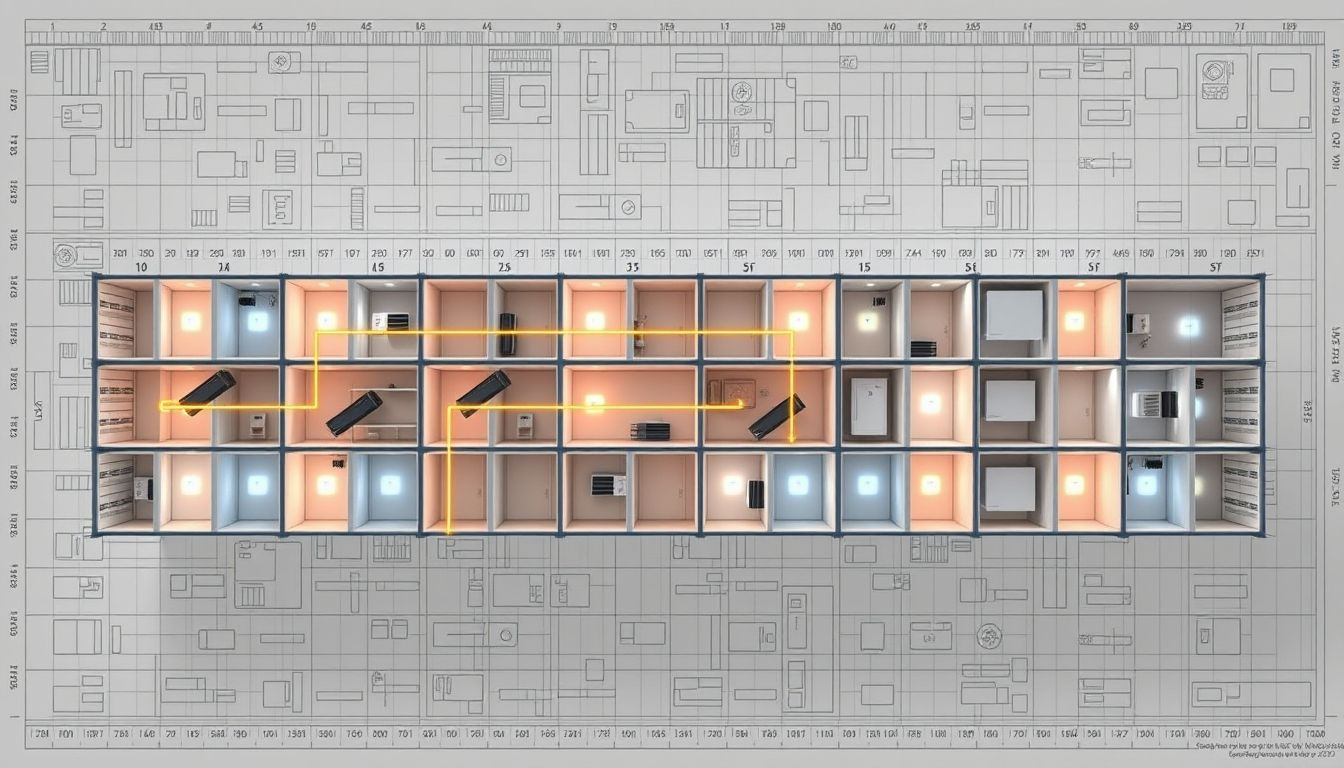

Portland’s Building Code Guide 96-11 explicitly addresses shipping containers. It provides a regulatory roadmap that classifies them as accessory structures rather than specialized hazards. That single decision reduces permitting complexity across four dimensions:

Classification: Most containers under 200 square feet and 10 feet high avoid permits entirely. Larger builds fall under Group U or S designations, which still follow standard residential streams—not commercial queues.

Structural Simplicity: Containers can sit directly on compacted grade or existing slabs—no need for deep-set foundations or anchoring hardware.

Egress Simplification: Standard container doors satisfy egress codes, provided one opening meets 3’ x 6’8” minimums. No need for cut-ins or expensive door retrofits unless adding a second unit.

Permit Costs: A typical container ADU costs between $2,000 and $5,000 in permits, with processing times of 60–90 days. This approach makes shipping container garages an affordable and cost-effective solution for homeowners, especially when compared to the higher costs and longer timelines often associated with traditional garages.

One standout example is the Morgan build in Madison South. This two-container ADU (640 sq. ft.) used high-cube 40-foot units stacked side-by-side. Built in under four months, it was fully permitted, entered the rental market rapidly, and added $200,000 in appraised value to the property. That gain came with less regulatory overhead and a significantly lower cost than an average bathroom remodel in Seattle or constructing traditional garages.

When considering container options and configurations, you can choose a single container for a compact, affordable garage or two containers for increased space and versatility, depending on your storage or parking needs.

Opting for a used container is not only environmentally friendly but also an affordable and suitable choice for garage projects, provided you inspect for rust and structural integrity.

Compared to traditional garages, container garages offer greater cost effectiveness, flexibility, and faster construction, making them a modern and practical alternative.

The city’s permitting philosophy centers on functional compliance rather than structural overengineering. If the container is safe, accessible, and well-laid-out—it’s acceptable.

That insight flips the DIY paradigm: you don’t need to scale back your dream; you just need to align it with a prep-friendly permit environment. For homeowners seeking affordable and versatile solutions, shipping container garages are a great option in Portland.

Container Options and Modifications: Choosing and Customizing for Your Needs

When it comes to building a container garage or carport, you have plenty of options to tailor the space to your needs. If you require more space for multiple vehicles or want to create a workshop with extra storage, combining two shipping containers side by side or end to end can give you the width and flexibility you need. For smaller projects or limited available space, just one shipping container may be enough to store a single car, tools, or equipment.

Used containers are a popular choice for those looking to save money, but it’s important to inspect them carefully for rust, dents, or structural damage before making a purchase. Once you’ve selected your container, modifications can transform it into a highly functional storage space. Adding personnel doors makes access easier, while installing windows brings in natural light and improves ventilation. Shelves and custom storage solutions can help you organize tools and equipment efficiently, and upgraded garage doors or security features can enhance both convenience and safety.

Think about your specific requirements—what vehicles or equipment will be stored, how much storage space you need, and what features will make your container garage or carport most useful. With the right planning and modifications, you can create a secure, efficient, and attractive storage solution that fits your property and your lifestyle.

A Tale of Two Cities: Where Code Meets Culture (And Economics)

So, why does Portland embrace container innovation while Seattle resists it? The answer lies at the intersection of planning culture, political history, and market pressures.

Portland’s ethos leans toward inclusion, housing innovation, and green experimentation. It actively aligns goals around affordability, density, and environmental sustainability—making container construction a natural fit.

Seattle, in contrast, navigates a more risk-averse terrain:

Land-use politics are shaped by strong industrial preservation mandates.

Port authorities influence zoning restrictions near freight corridors.

Labor interests resist modular innovation that could reduce total job hours.

Data reveals significant divergence:Portland processes 3–4x more ADUs per capita than Seattle.

Container ADUs represent a growing share of those permits.

Neighborhoods like Madison South report 25–34% property value increases from container units.

Seattle? It lacks the dataset to even measure success—because so few container builds make it through permitting.

The economic cost of code resistance is clear:Seattle owners face uninsurable structures

Lenders label containers “non-comparable appraisals”

Builders experience timeline uncertainty that kills cash flow projections

Where Portland green-lights incremental housing wealth, Seattle turns the same structures into asset risk.

Security and Safety Features: Protecting Your Investment

A major advantage of shipping container garages and carports is their inherent security. Made from heavy-duty, durable materials, shipping containers are designed to protect valuable cargo from theft and harsh weather during long ocean journeys—making them a natural fit for secure vehicle storage on your property. However, to maximize protection for your vehicles and equipment, consider adding extra security features tailored to your needs.

High-quality locks, reinforced garage doors, and personnel doors with deadbolts can deter unauthorized access. For added peace of mind, install alarms or surveillance cameras to monitor your container garage or carport. If you’re storing especially valuable items, consider motion-activated lighting or even a security system that alerts you to any unusual activity.

Safety is just as important as security. Make sure your container is properly ventilated to prevent condensation and mold, and keep walkways clear to avoid accidents. Regularly inspect the structure for any signs of wear or damage, and address issues promptly to maintain a safe environment. By investing in the right security and safety features, you’ll protect your investment and ensure your container garage or carport remains a reliable storage space for years to come.

Container Construction Intelligence: Recognizing the Patterns That Predict Success (or Condemnation)

ModBetter’s analysis across dozens of container builds reveals repeatable patterns. Success isn’t random—it follows observable rules that DIY builders can learn from. Over-the-counter approvals for sheds, shelters, and canopies make container projects more versatile, allowing for a wider range of storage and protection solutions.

Pattern 1: Classification Drives Complexity

Containers classified as “residential accessory structures” (Group U) face fewer hurdles. Once a structure is labeled “specialized” or “occupancy unknown,” it falls into regulatory purgatory.

Intelligence Tip: Confirm occupancy group upfront. Mislabeling at the start leads to misrouting later.

Pattern 2: Permit Cost-to-Project Size Ratios

Projects succeed when pre-construction costs stay under $10,000 for <800 sq. ft. structures. Beyond that, timelines spike and ROI drops.

Red Flag: Any city quoting >$20K in pre-permit costs likely requires high engineering effort. Seek reassessment or redesign.

Pattern 3: Labor Ecosystem Symmetry

Cities with welding-savvy contractors who also understand local code (like Portland’s small builder network) enable container builds. Places dominated by large traditional contractors resist adaptation.

Signal to Watch: Cities with “maker-fab” communities support container innovation organically.

Pattern 4: Regulatory Maturity

Published container guidelines reduce permitting friction and builder churn. Jurisdictions like Portland advertise code transparency, minimizing surprises.

Tool You Can Use: Portland’s Building Guide 96-11 operates as a de-facto national playbook for container feasibility.

Pattern 5: Political-Goal Alignment

When a city’s general plan embraces density, sustainability, or missing-middle housing, container projects align with policy—not rebel against it.

Strategic Advantage: Show how your container plan advances the city’s stated goals.

Broken System Indicators:

Projects require permit expeditors just to get routed.

Multiple conflicting department comments.

No published guidelines on containers.

Opportunity Signals:

Over-the-counter approvals for sheds and ADUs.

High accessory permit velocity (e.g., ADUs, backyard structures).

Fee transparency by square footage, not construction material.

Success isn’t luck—it’s pattern recognition.

Maintenance and Upkeep: Ensuring Longevity

To get the most out of your shipping container garage or carport, regular maintenance is key. While shipping containers are built to withstand harsh weather and heavy use, a little upkeep goes a long way in preserving their structural integrity and functionality. Start by inspecting your container regularly for signs of rust, corrosion, or damage—especially around the roof, doors, and corners where water can collect.

Keep the container clean and dry inside and out. Remove debris from the roof and ensure drainage is working properly to prevent standing water. Applying a rust-inhibiting paint or coating can help protect the corten steel from moisture and extend the life of your container. Check seals around doors and windows to make sure they remain weather-tight, and lubricate hinges and locks to keep them operating smoothly.

By following a simple maintenance routine, you’ll protect your container garage or carport from the elements, avoid costly repairs, and ensure your storage space remains functional and secure for years to come.

Troubleshooting Common Issues: What to Watch Out For

Even with the best planning and maintenance, issues can occasionally arise with your container garage or carport. Common problems include leaks from worn seals or roof damage, rust developing in areas where paint has chipped, or structural concerns from accidental impacts or shifting foundations. If you notice water pooling inside, trace the source—often it’s a minor gap in a door seal or a clogged drainage point on the roof.

Rust should be addressed as soon as it appears: clean the affected area, treat it with a rust converter, and repaint to prevent further corrosion. If you spot dents or warping that could affect the container’s structural integrity, consult a professional to assess and repair the damage. Regular inspections are your best defense—catching small issues early can save you significant money and hassle down the line.

By staying vigilant and proactive, you’ll keep your container garage or carport secure, functional, and ready to meet your storage needs for the long haul.

Next Steps for DIY Builders: How to Shift from Confusion to Coordination

If you’re a DIY container builder, your first decision shouldn’t be “Which container should I buy?”

It should be: “How will my jurisdiction classify this?”

Step 1: Decode Your Local Regs

Start not with a designer, but with your local planning desk. Ask:

What’s the required occupancy classification for this type of structure?

Are containers permitted outright or treated as “other structures”?

Step 2: Use Portland’s Model, Even If You’re Not There

Portland’s Guide 96-11 outlines how best practice looks. Use it to:

Benchmark egress and insulation specs.

Draft your own classification memo.

Push local officials to clarify terms.

Step 3: Design to Match “Low-Friction Thresholds”

Many jurisdictions allow ≤200 sq ft structures without full permits.

< 10 ft height

Single egress

Grade-exempt foundation

A single container is often the simplest and most permit-friendly option for a shipping container garage.

Shrink the build to clear the red tape.

Step 4: Don’t Design Blind

Skip the rookie error of designing your dream build before confirming code path. Confirm:

Which code applies: IBC or residential?

What use triggers special routing?

What documents are required to apply?

Reverse your process: Classify, then design.

Step 5: Use Permit Intelligence Tools

At ModBetter, we offer scan tools that cross-reference local zoning overlays, permit data, and approval timelines by jurisdiction. Using our pre-check model, you can score feasibility before the first draft.

DIY Shipping Container Conversion Guide FAQ

Q: Can I use Portland’s permit model elsewhere?

A: Yes, as a benchmark. While each city has unique rules, Portland’s framework is a playbook for how to treat containers as legitimate builds.

Q: What’s the biggest financial risk for DIYers?

A: Permitting costs and delays. Surprise engineering needs can double your pre-construction budget.

Q: Why do insurers or lenders avoid container projects?

A: In cities like Seattle, low precedent and nonstandard classifications make containers harder to appraise, insure, or underwrite. Not so in Portland.

Q: Do containers always save money?

A: Only where permitting doesn’t erase savings. The steel’s cheap. Red tape isn’t.

Navigating the Invisible Walls of Container Construction

A 20-minute drive. Two boxes of steel. Two very different outcomes. That’s the reality of container construction in America today. In the war between innovation and inertia, between builders and bureaucrats, distance matters less than definition.

Seattle turned a promising structure into an insurance liability. Portland transformed an accessory build into $200,000 in property value.

That’s not a design problem—it’s an intelligence problem.

At ModBetter, we surface the patterns that predict project viability through real permit data, builder alignment, and code interpretation. Before you pick up a grinder or schedule delivery on a 40-foot cube, run a feasibility scan. Know your classification options. Plan for policy, not perfection.

Don’t design in the dark. Build with foresight.

👉 [Download Our Free Floor Plan Guides Now]

Be smarter than your structure. Build on intelligence.